Currently in development!

This concept is in the concept phase for now. In the past we made a succesful prototype of a manual injection molding machine including a clamping unit. This has been used for small production runs and workshops. Currently we are working to improve this concept to a grown up product. Let us know if you would be interested in a machine like this!

Overview of the concept

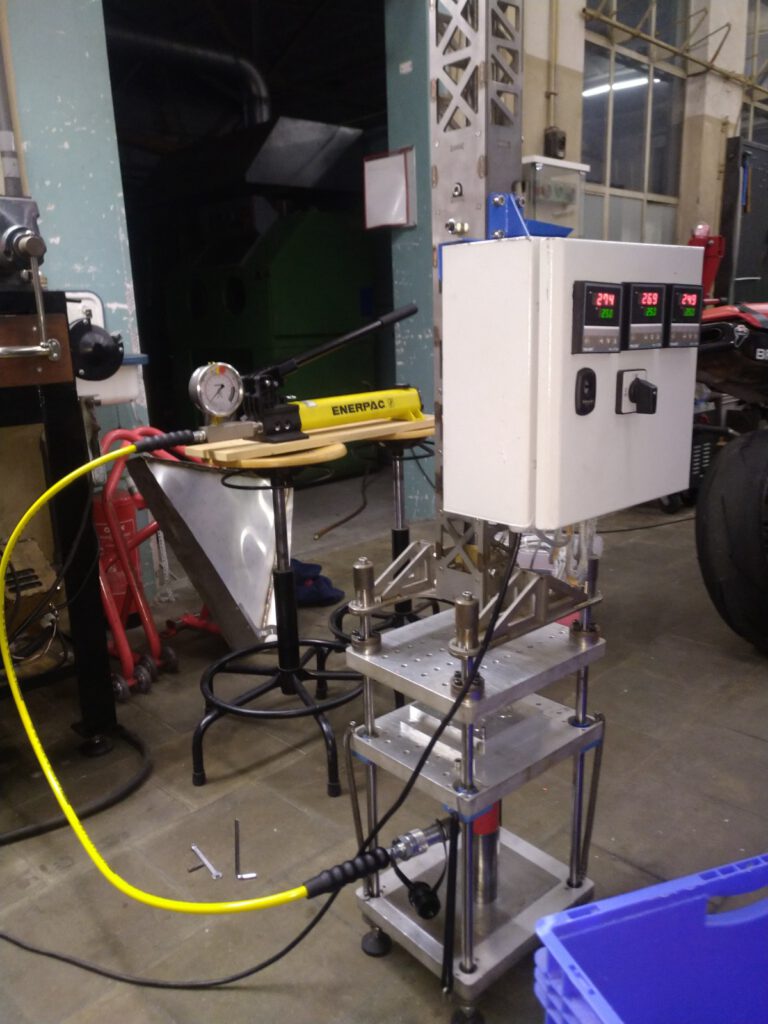

We’ve produced a prototype in 2018 for a recycling project in Zwolle, during the Stadsfestival that year. We used it to recycle drinking cups into tokens.

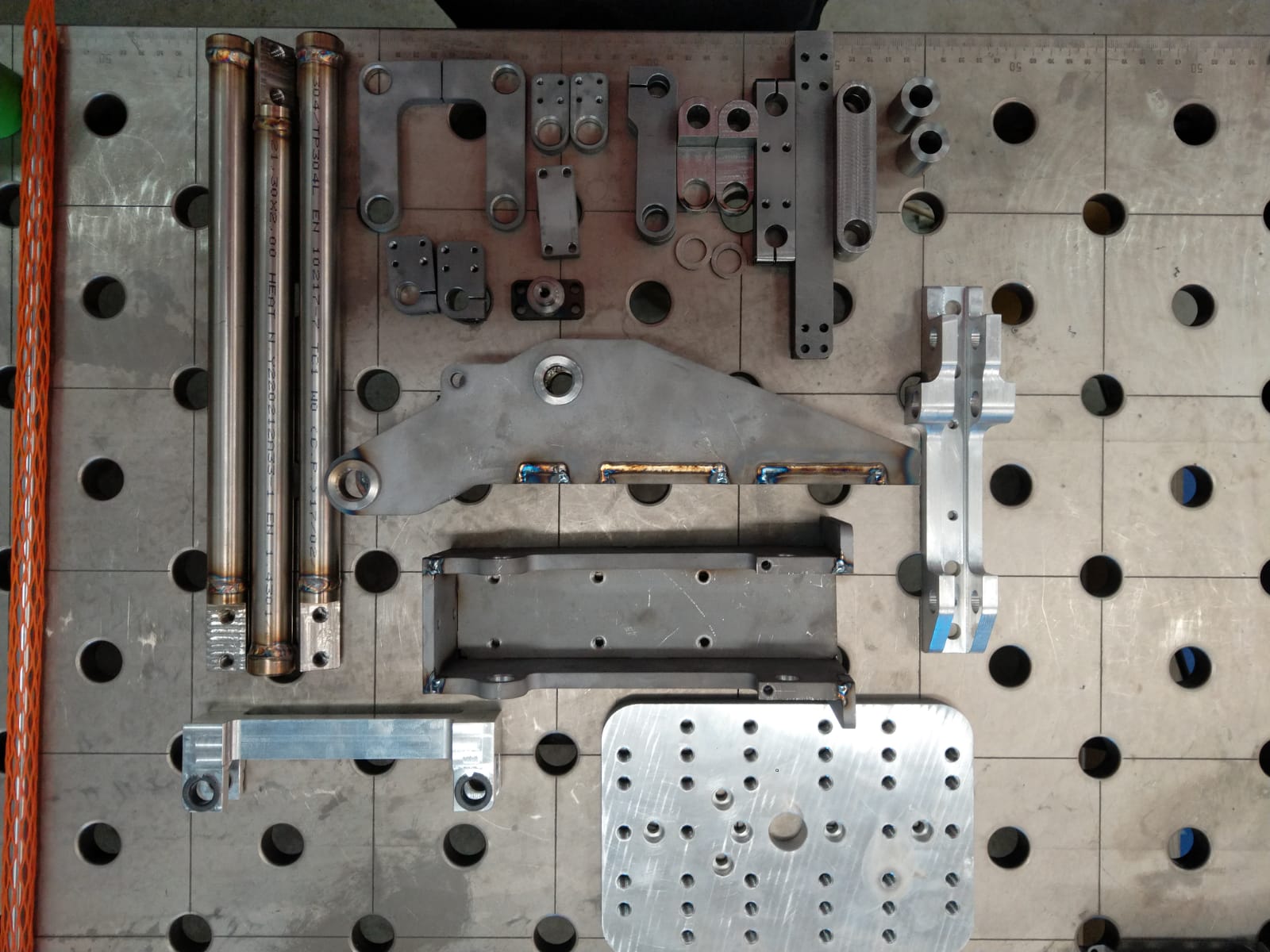

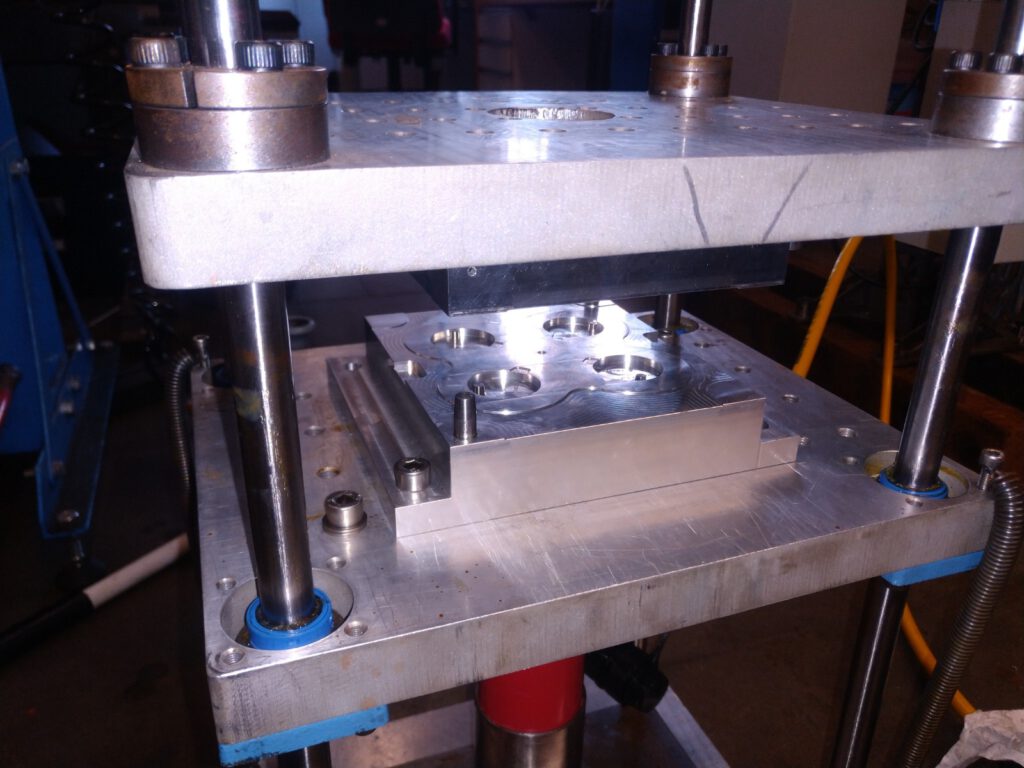

The machine has a 26 mm plunger for injection and a heated barrel for melting the plastic. The machine has a vertical arangement, making the footprint really small. A clamping unit is made to hold the mold and hydraulic cylinder to open and close the molds. This prototype did not have an ejector system.

This machine proved capable of producting small series of injection molded parts. It was especially suitable to make parts with a marble effect. Some drawbacks we discovered during working with the machines and by analysing the design:

- Limited injection pressure

- No ejector to eject parts.

- Design to complex to produce for customers

- Injection can be inconsistent.

- No screw means longer times to melt the plastic.

Currently we are working on 2 concepts to improve upon this, one is aimed for automatisch production with industrial performance while the version for recycling is aimed still for manual operation, while being robust and efficient to manufacture.

Are you interested in a concept like this, then let us know!