Introducing the Dispoflow S30/600

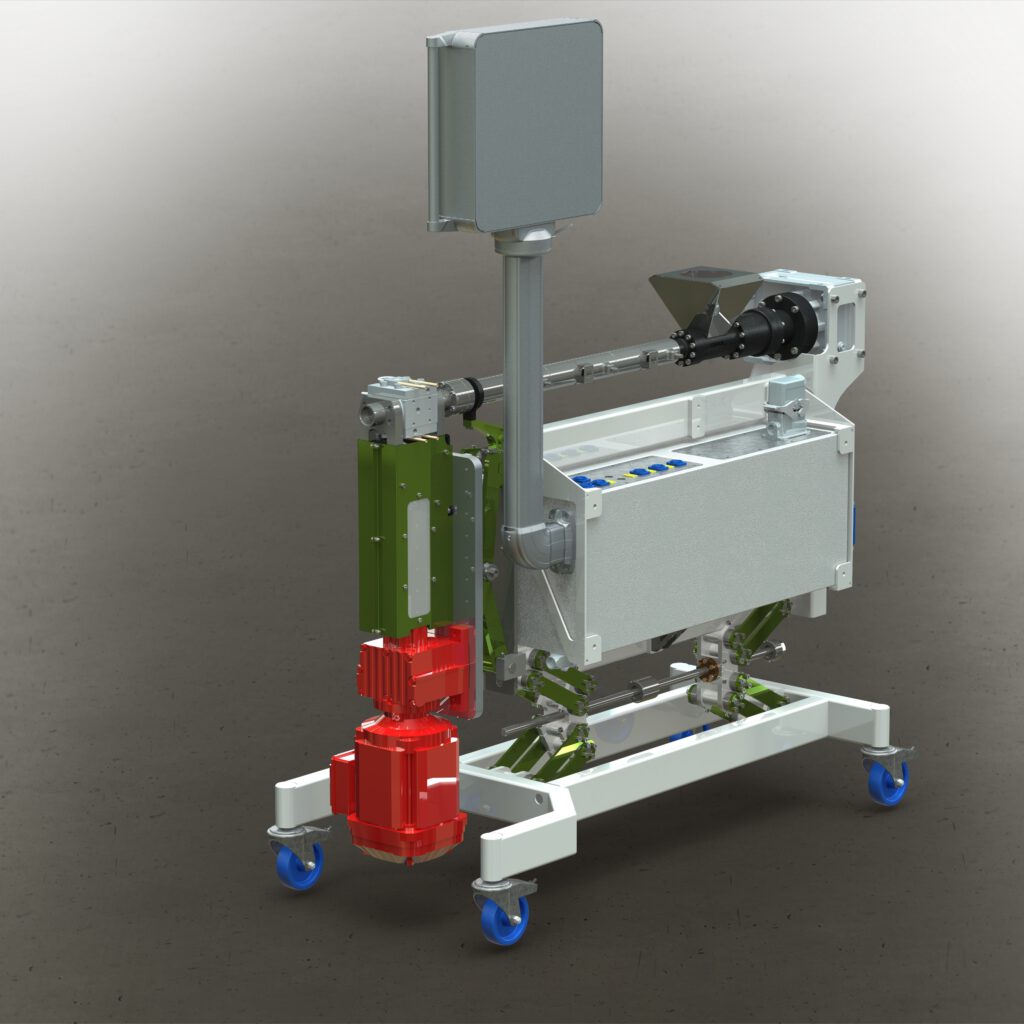

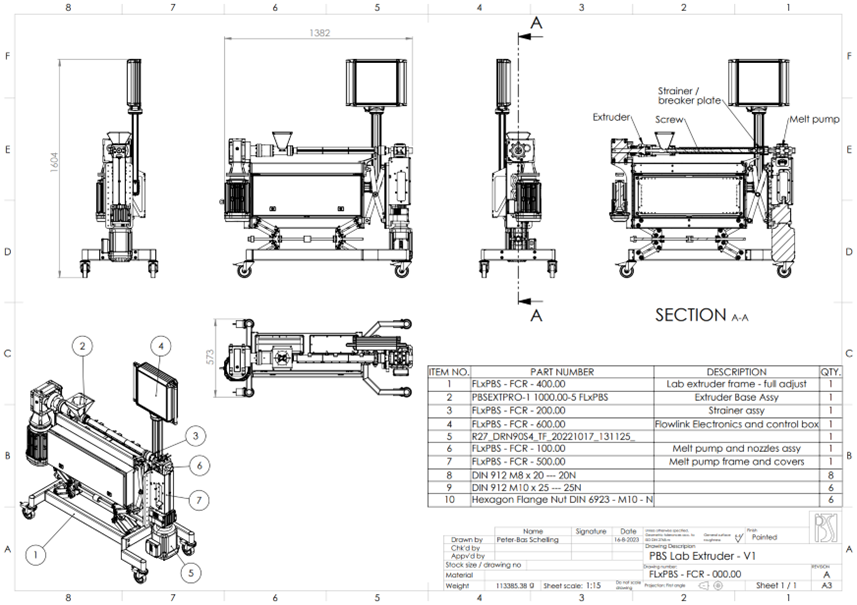

The Dispoflow extruder S30/600 is a high-performance extrusion solution, based on the industry-standard tabletop extruder 30/600. Designed for precision and versatility, this extruder comes equipped with a melt pump and is seamlessly controlled by the advanced “Flow-Connect” controller developed by flowlink BV.

Key Features of the Dispoflow S30/600

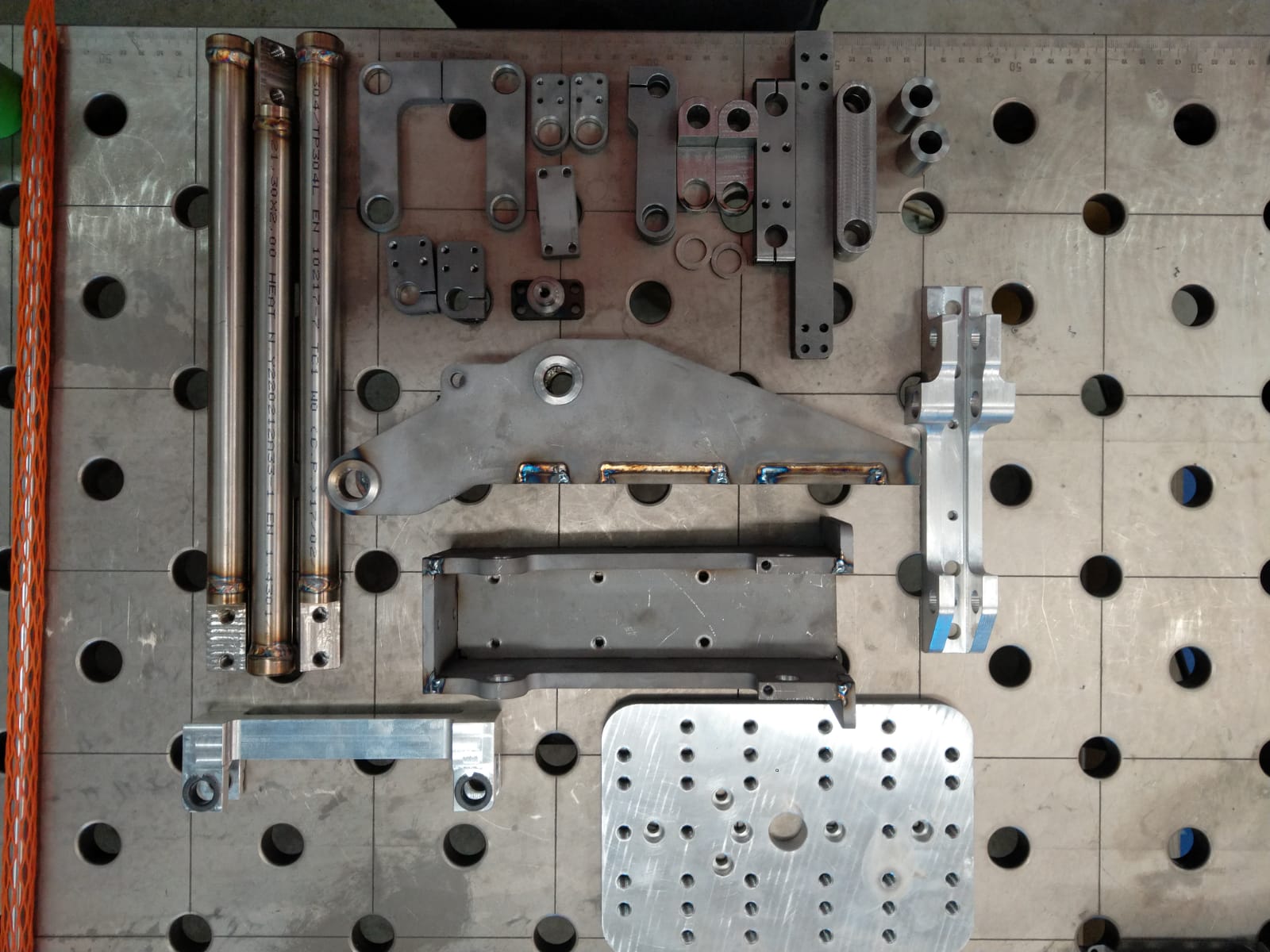

- Height-Adjustable Frame: The extruder package is mounted on a height-adjustable frame, which also features an additional horizontal lift for easy changeovers, cleaning, and maintenance tasks. This design enhances operational flexibility and convenience.

- Compact and Mobile: The entire extrusion system is designed to be compact and mobile, weighing less than 150 kg, making it highly adaptable for various setups and environments.

Benefits of the Melt Pump:

In this innovative concept, the extruder serves as a feed pump to the melt pump, offering a range of essential functions:

- Melting and Mixing: The extruder efficiently melts and mixes the polymer materials, ensuring uniformity in the process.

- Consistent Pressure and Temperature: It maintains a constant pressure and temperature while feeding the melt pump, which is crucial for achieving quality output.

- Higher Pressure Output: The integrated melt pump empowers the extruder to achieve higher pressures, reaching up to 350 bar. This feature is essential for demanding applications.

Additional Advantages of the Melt Pump in Processing:

- Pulsation Reduction: The melt pump effectively reduces pulsation, ensuring a smoother and more controlled extrusion process.

- Melt Swirl Minimization: It minimizes melt swirl, resulting in a more predictable and precise extrusion.

The Flexible Frame Design:

The horizontal adjustment feature of the frame offers flexibility for integrating various auxiliary equipment between the extruder and pump, including:

- Static mixers

- Breaker plates/filters

- Valves

- Measuring equipment

Furthermore, this versatile machine can also be fitted with vertical height adjustment, allowing precise control over the nozzle height within a specific range.

Experience cutting-edge extrusion technology with the Dispoflow extruder S30/600 and its advanced features that enhance efficiency and product quality.

Product sheet

Specifications

| Specs. Dispoflow extruder S30/600 | ||||

| Machine description | Single Screw extruder combined with melting pump, controlled by a Flowlink “Flowconnect” system. Lightweight and mobile design. | |||

| Machine Flow control description | Automatic extruder control based on pump speed while controlling the extruder speed to ensure consistant melting. | |||

| Physical specs | Weight | 150 | kg | Approximation |

| Length | 1210 | mm | Length without melt pump | |

| Width | 580 | mm | ||

| Height | 1610 | mm | Min height lowest frame position | |

| Min. Nozzle height from floor | 933 | mm | ||

| Max. Nozzle height from floor | 1053 | mm | With height adjustment fully extended | |

| Power specs | Machine Voltage | 400 | Vac | 3 phase |

| Extruder motor power | 3000 | W | ||

| Extruder heating power | 1800 | W | ||

| Melt pump motor power | 1100 | W | ||

| Melt pump heating power | 800 | W | ||

| Total peak power consumption | 6700 | W | ||

| Rated peak current | 16,75 | A | ||

| Heating zones extruder | 3 | |||

| Heating zones melt pump | 1 | |||

| Extruder specs | Screw diameter | 30 | mm | Standard multi-purpose with option for mixing tip |

| Length of screw (mm) | 790 | mm | ||

| Effective screw length | 600 | mm | ||

| Screw L/D ratio | 20 | |||

| Extruder motor Type | Euronorm DS100M2/IEC/FF215/TF | |||

| Extruder reductor type | Euronorm Hypoïde JKM48B | |||

| E-motor torque @ 50 hz | 10,1 | Nm | ||

| Gearbox reduction | 15 | |||

| Extruder motor efficiency | 87,1% | |||

| Extruder reductor efficiency | 92% | |||

| Effective Screw torque @ 50 hz | 121,25 | Nm | Other ratios available | |

| E-Motor speed @ 50 hz | 2840 | RPM | ||

| Screw speed @ 50 hz | 189 | rpm | ||

| Motor shaft diameter | 30 | mm | ||

| Motor reductor output shaft type | Hollow | |||

| Melt pump specs | Melt pump motor type | SEW-Eurodrive R27 DRN90S4/TF | ||

| Pump motor torque @ 50 hz | 7,22 | Nm | ||

| Motor efficiency | 84,5% | |||

| Motor speed @ 50 hz | 1455 | RPM | ||

| Gearbox reduction | 10,13 | |||

| Output speed @ 50 hz | 144 | RPM | ||

| Effective output torque @ 50 hz | 61,8 | Nm | ||

| Pump stroke / rev | 2,78 | CC/rev | ||

| Volumetric efficiency | 95% | |||

| Max theoretical troughput pump | 379,3 | CC/min | ||

| 22760,0 | CC/hr | |||

| 22,8 | dm³/hr | |||

| Max rated pump output pressure | 350 | bar | ||

Options and pricing

Our Dispoflow extruder S30/600 takes customization to the next level with its modular design. We understand that your requirements may vary, and that’s why we offer the flexibility to tailor the machine according to your specific needs and preferences. Custom screw design are available on request.

Prices to be announced soon!

For enquiries and a quotation, contact us via the contact page by clicking the button below